WOOD PRODUCTS 2653 Warfield St. Fort Worth, TX 76106 |

FLAMEPROOF COMPANIES

flamesafe.co FLAMEPROOF LUMBER Hotline: 800-333-9197 8am-5pm (CST) |

|---|

Ph: 817-740-9197 After Hours: 817-658-9197 email: fireprod@aol.com |

|---|

| HOME | Testing |

Vacuum Pressure Impregnated - Kiln Dried After Treatment (KDAT) Lumber, Plywood, Timber, Shake Shingles, Architectural Millwork, Specialty Treatments |

Flame Safe Identifying Stamp for flameproof lumber Flame Safe Identifying Stamp for flameproof lumber |

Depending on building occupancy, location of the material in the building and the presence of sprinklers, fire retardant wood materials are permitted under code requirements. To comply with the code standards, wood and wood products must meet the ASTM E84 test standard (Surface Burning Characteristics of Building Materials). Flame Safe flameproof lumber is kiln dried to a moisture content not to exceed 19%.Pitch in the wood is crystallized permitting interior and exterior finishes to be easilly applied. Flame Safe’s finished moldings and trim is kiln dried to a maximum moisture content of 6 to 12 % depending on the species and specific use.When kiln dried, Flame Safe fire retardant treated wood becomes lighter and stronger, maximizing it's structural uses.

|

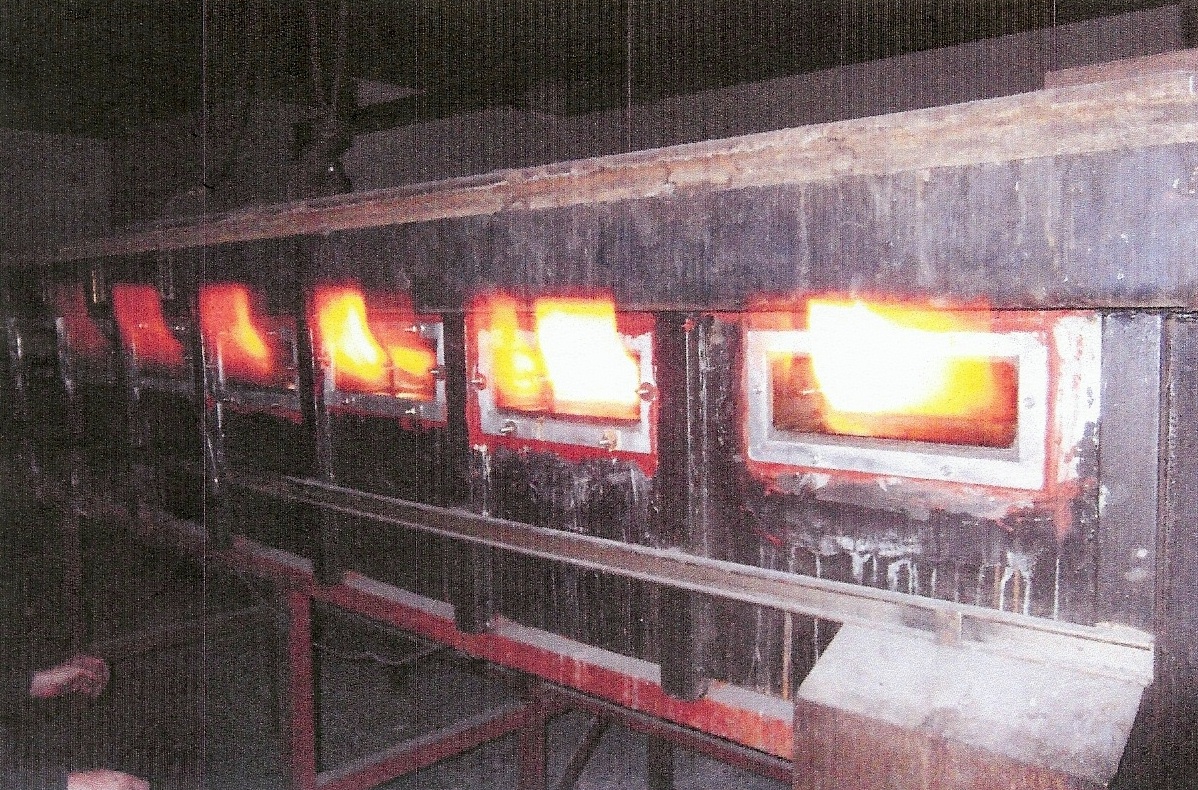

ASTM E84 TEST CHAMBER ASTM E84 TEST CHAMBER |

The test chamber is rectangular being 17-3/4" to 24" wide, 12" in height and 25' in length. Multiple windows are located in the upper half of the wall of the test chamber so the test samples can be observed from outside the fire chamber. This test method determines the relative burning behavior of the fire retardant wood by observing the flame spread along the specimen. The flame spread is determined by distance the flame travels and the rate at which the flame front advances during the first 10 minute exposure the test continues for an additional 20 minutes. Smoke generation is recorded and indexed. |

| Wood and wood based products are highly desirable due to their appearance and versatility. |

American Standard of Testing Materials (ASTM) E84 classifications |

|

| Class | Flame Spread |

| ASTM E84 A or UL723 TYPE 1; NFPA 255 | 0-25 |

| ASTM E84 B or UL723 TYPE II | 26-75 |

| ASTM E84 C or UL723 TYPE III | 76-200 |

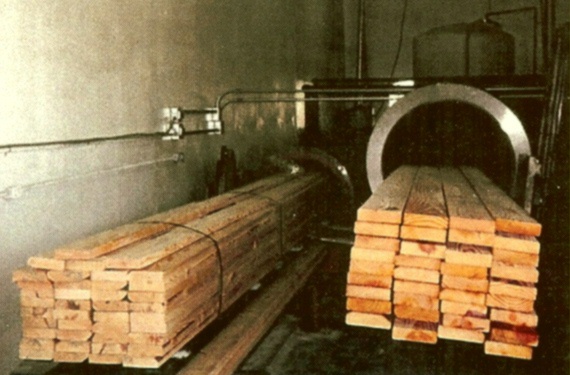

VACUUM PRESSURE IMPREGNATION Lumber is loaded into a treatment cylinder. The door is sealed and a vacuum is applied. During this stage, most of the moisture and the air is removed from the wood cells. The vacuum in the cylinder causes the cylinder to fill with Flame Safe's proprietary Fire Retardant. Pressure is raised in the cylinder forcing the fire retardant solution into the wood. The pressure and times varies depending on the species of the wood, the commodity being treated, the cross sectional area, and the amount of the Fire Retardant solution to be impregnated into the wood. The pressure in the cylinder forces the remaining fire retardant solution to flow back into a holding tank. Another vacuum is applied, removing the excess fire retardant solution from the wood. The lumber, plywood or timber is loaded onto a tram that services a gas fired forced air kiln. |

KILN DRYING AFTER TREATMENT Heated air is used to extract moisture from the wood. A gas fired forced air convection system removes most of the moisture from the wood after treatment. The moisture laden air is dehumidified. The drying rate is monitored to prevent cracking in the lumber. Lumberd is kiln dried to a moisture content not to exceed 19%. . Pitch in the wood is crystallized permitting interior and exterior finishes to be easily applied. When kiln dried, Flame Safe fire retardant treated wood becomes lighter and stronger, maximizing it's structural uses. |

Lumber in Treatment cylinder Lumber in Treatment cylinder |

Flame Safe's experienced, qualified staff offers technical support to assist our customers in selecting the Flame Safe product necessary to meet fire safety and building code requirements. Based in Fort Worth, Texas we ship not only to Dallas, San Antonio, Austin, Oklahoma City, Shreveport, Houston, Lubbock, areas local to us, but across the United States whether it be Miami, New York, Seattle, Portland, Los Angeles, San Francisco, Las Vegas, Boston, Philadelphia, Des Moines, Dayton, as well as internationally.

Fire Codes are written and enforced to save lives and property. Flame Safe fire retardant coatings and products are compliance tested.

Many flameproof products presently on the market do not have testing by accredited third party testing agencies to back their claims. The credibility of Flame Safe’s products are well documented by accredited 3rd party testing agencies, including Intertek, Underwriter’s Laboratories (UL), Southwest Research Institute (SWRI), Universal Laboratories, Diversified Testing, United States Testing, Western Fire Center, Maxim Technologies-Southwestern Laboratories, U.S. Forestry Department, FEMA, Forestry Commission of New South Wales, Australia, European Institute for Fire Research, Ontario Research of Canada, and more.

| ACCREDITED 3RD PARTING TESTING ASTM E84 CLASS “A” - UL 723 TYPE 1 - NFPA 255 - UBC 42-1 |

|---|

|

|

Interior FireRetardant Plywood |

Exterior FireRetardant Plywood |

Interior FireRetardant Timber |

Exterior FireRetardant Timber |

|---|

Flame Safe Wood Products fire retardant lumber,plywood, timber and wood specalties have been tested by accredited third party testing agencies. Flame Safe warrants it’s products to perform as tested and will furnish test reports upon request, in addition to those published on FLAME SAFE'S web site

| Fire Retardant Wood & Fire Retardant Plywood Treatments |

| Vacuum Pressure Impregnation and Kiln Dried After Treatment (KDAT) |

| Fire rated lumber - Fire rated plywood - Fire rated wood specialties - Fire rated timber |

Exterior fire retardant lumber ● interior fire retardant lumber ● exterior fire retardant plywood ● interior fire retardant plywood ● interior fire retardant wood specialties ● exterior fire retardant wood specialties ● exterior fire retardant timber & timbers ● interior fire retardant timber & timbers ● architectural millwork, molding & trim ● fire retardant OSB ● fire retardant particle board ● fire retardant MDF ● fire retardant shingles ● fire retardant Insulation ● fire retardant treated special orders

|

Flame Retardant coatings can save lives and property Hotline: 800-333-9197 8am-5pm (CST) -- Ph: 817-740-9197 After Hours: 817-658-9197 -- email: fireprod@aol.com |

|---|

| 2650 Warfield Avenue, Fort Worth, TX 76106 Ph: 1-800-333-9197 or 1-817-740-9197 |

| HOME | TESTING | FIRE RETARDANT COATINGS | ABOUT US | CONTACT US |

The information contained herein is the property of Fire Prevention Technologies d/b/a Flame Safe Chemical Corporation and Flame Safe Wood Products, Inc . copyright 1990 Revised 8/20/2009, Revised 2012